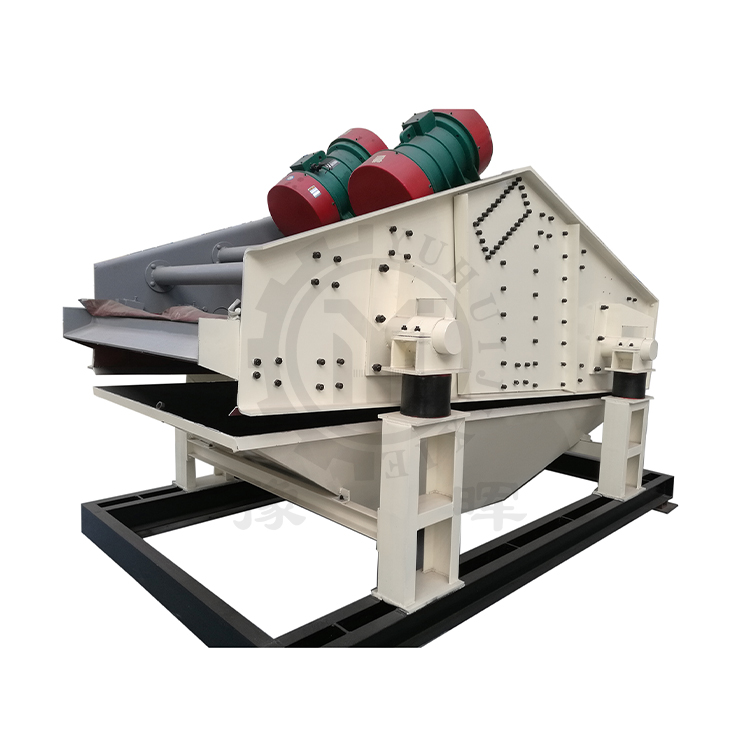

SF Flotation Machine

Introduction of SF flotation machine

SF flotation machine is used to separate non-ferrous metals, ferrous metals, precious metals, non-metallic minerals and chemical raw materials, recycle the useful minerals. The device has the following characteristics: the giant inspiratory volume, low power consumption. Each slot has three features, that’s inhale, absorb the pulp and flotation. It’s automatic flotation circuit; there is no need of any auxiliary equipment. The configuration is horizontal, which can ease the changes of process. Slurry circulation is reasonable; it can reduce the coarse sand deposits to the greatest degree. With pulp surface-controlled device, it’s convenient to adjust.

Structure of SF flotation machine:

1).An impeller is equipped with a backward-type double-sided blade, thus the double-loop of the pulp in tank can be realized

2).There is a larger space between the impeller and the cover plate, and so the inspiratory is giant.

3).The impeller circumferential velocity is low, so the wearing parts’ life span is long.

4).The tank is forward-style, the dead angles are small, and the bubble velocity is fast.

Features of SF flotation machine:

1).Large inspiratory capacity, low power consumption.

2).It does not need any auxiliary equipment as very slot forms the flotation circuit independently by setting inspiration, sucking pulp and flotation as a whole.

3).Reasonable pulp circulation, which can minimize precipitation of coarse sand

4).With automatic control equipment, making it easily to do adjustment.

Application of SF flotation machine:

SF Flotation machine is widely used for roughing, concentrating and counter-flotation of nonferrous metal that includes copper, lead, zinc, nickel and molybdenum, ferrous metal and nonmetallic mineral.

Working Principle of SF flotation machine:

When it works, the motor drives the impeller to revolve, so the centrifugal effect and negative pressure are produced. On one hand, ample air is absorbed and mixed with mineral slurry, on the other hand, the mixed mineral slurry is mingled with additive, meanwhile, the foams are thinning, the mineral is bounded with foams, and floats up to the surface of mineral slurry and the mineralized foam is formed. The liquid surface can be adjusted with the height of adjustment flashboard, so that the useful foams are scraped with squeegee.

Main Technical Parameters:

|

Model

|

SF0.37

|

SF0.7

|

SF1.2

|

SF2.8

|

SF4

|

|

Trough volume(m3)

|

0.37

|

0.7

|

1.2

|

2.8

|

4

|

|

Impeller diameter(mm)

|

300

|

350

|

450

|

550

|

650

|

|

capacity(m2/min)

|

0.2-0.4

|

0.3-0.9

|

0.6-1.2

|

1.5-3.5

|

0.5-4

|

|

Impeller speed(r/min)

|

352

|

400

|

312

|

268

|

238

|

|

Model of motor

Power of motor(kw)

dimensions(mm)

single trough weight(kg)

|

①Y90L-4

|

①Y100L2-4

|

①Y132M2-6

|

①Y160L-6

|

①Y180L-6

|

|

②Y90S-4

|

②Y90S-4

|

②Y90S-4

|

②Y90S-4

|

②Y90L-4

|

|

|

①1.5

|

①3

|

①5.5

|

①11

|

①15

|

|

|

②1.1

|

②1.1

|

②1.1

|

②1.1

|

②1.5

|

|

|

700X700X750

|

900X820X950

|

1100X1100X1100

|

1700X1600X1150

|

1850X2050X1200

|

|

|

468

|

600

|

1373

|

2338

|

2660

|

Note: The technical parameters above are just for your reference. If there is any change, all parameters and overall dimension are subject to operating instructions. Any questions please feel free to contact us.

We adhere to the principle of " Quality and Honesty fist"

Choose YuHui, you choose the best.

Now,please call us at: 0086-371-55018888 or email us at: hnyhks@hotmail.com